From traditional dial-up phones to digital mobile phones with one hand, or from traditional fuel locomotives to electric locomotives capable of digital communication, switching power supplies also have the same differences between the new and old generations. The control and monitoring of the early power supplies were designed using analog lines. , Usually through various external interfaces, such as: output voltage modulation (through the power supply to provide a specific voltage level to the control end of the power supply, remotely modulate the power supply Output voltage), power status display (the simplest and most common way is mostly the color change of the LED), and Power Good signal (after the output voltage of the power supply is normally output, it will immediately provide a signal to notify the system side), etc... These are common monitoring requirements. The above method may be suitable for most applications, but with the development of science and technology, the design and application of digital intelligence and automation control are becoming more and more extensive. The traditional analog control and monitoring interface may not be able to meet the need to quickly grasp power information and design. The user whose condition is handled automatically by the product.

MEAN WELL's programmable power supply provides two different communication interfaces, PMBus and CANBus, to meet customer needs.

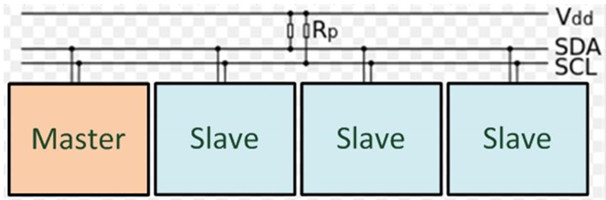

PMBus (abbreviation for power management bus) uses two-way communication: serial data line (SDA) and serial clock line (SCL), each power supply (slave) only needs 3 signal lines (including one GND line) to connect To the BUS end, the demand for controlling and monitoring the information of the power supply can be achieved through the controller (master). This can not only greatly reduce the use of control and signal lines, but also reduce the number of contacts on the line, reduce the probability of line failure, and increase the convenience of control. PMBus has a wide range of applications, and the monitoring requirements for power supply status are the most common in industrial automation application equipment and communication application equipment. Figure 1 shows the PMBus version and rate information used by MEAN WELL. The advantages and disadvantages are as follows.

Advantages: common agreement, easy for designers to import.

Disadvantages: weak anti-noise interference ability, suitable for short-distance communication.

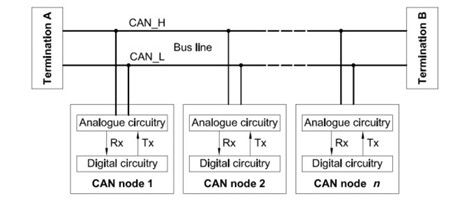

CANBus (controller area network) uses two-wire differential (CANH and CANL) transmission technology, which was originally developed to replace the complicated internal wiring of a car. But because it has a high degree of resistance to electrical noise interference and self-debugging capabilities, it has gradually been widely used in industrial and automation systems, including the power supply industry. Figure 2 shows the CANBus version and rate information used by MEAN WELL. Its advantages and disadvantages are as follows.

Advantages: High noise interference tolerance and relatively robust.

Disadvantages: The protocol is self-defined by MEAN WELL, and some command functions may need to be adjusted for the project.

Here are two actual cases, respectively using the communication interface of PMBus and CANBus.

Application: Unmanned truck

Model: RPB-1600-48 (Built-in PMBus communication)

Communication interface: PMBus

This application uses two RPB-1600-48 to be installed in parallel in the charging station of the unmanned truck in the logistics warehouse. When the truck returns to the charging station, the system will judge the connection status of the port and then use the PMBus to turn on the charger to charge the battery. The system will also select the appropriate charging current to charge the 6 battery packs of the truck through PMBus and send back charging information and power status through communication. Figure 3 is a schematic diagram of an unmanned guided vehicle.

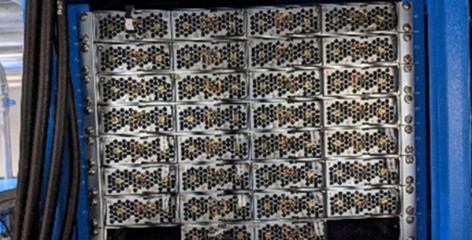

Application: National Synchrotron Radiation Research Center

Model: DRP-3200-48CAN (optional CANBus communication)

Communication interface: CANBus

This case requires multiple sets of 96kW high-power power supply systems, using the power output from the power supply system to drive an all-solid-state radio frequency power amplifier (Radio Frequency Power Amplifier). In order to match the application with the best power efficiency, the output voltage of the power system must be able to cover the 42Vdc ~ 54Vdc modulation range. DRP-3200-48CAN supports CANBus communication, supports 30 simultaneous online functions of a single system, and achieves precise voltage regulation requirements through communication commands. Furthermore, multiple power systems are not connected in parallel, and the bus voltage of each power system needs to be adjusted synchronously during experiments. To achieve synchronization and remote control, it is bound to be achieved through external controllers and communication protocols. At the same time, use the controller to modulate the output voltage, and the accuracy must meet the precision requirement of plus or minus 1%. Under this premise, the fully digital intelligent power supply design coupled with the robust anti-noise CANBus protocol makes it possible to remotely monitor the power supply system in a networked manner. Figure 4 is the actual configuration diagram of the 96kW high-power power supply system.

The MEAN WELL programmable power supply with communication function not only makes complex control and monitoring simple. The model is suitable for various applications, including general applications: RSP-1600/2000 and DPU-3200, cabinet applications: RCP-1600/2000 and DRP-3200, and fanless or water-cooled applications: UHP-1500/2500 and PHP -3500/3500-HV etc. With the characteristics of flexibility, multiple applications, etc., it is suitable for applications requiring intelligent control and monitoring.